How to convert 1 gallon of liquid gasoline into 160 gallons of highly combustible fuel vapor and increase your nation’s fuel supply by 16,000%

Getting Off Oil, Latest news, World news Tuesday, April 3rd, 2012

Offshore oil rigs flare the energy equivalent of 40 to 60 billion gallons of gasoline each year.

How much does 1 gallon of liquid gasoline displace as a vapor? The saturated vapor volume of an average gallon of liquid gasoline when fully evaporated is 160 gallons of vapor at 60° F and sea level. When you convert 1 gallon of gasoline into 160 gallons of highly combustible fuel vapor you increase your nation’s fuel supply by 16,000% (16,000% of 1 is 160). If you paid $5 for just one gallon of liquid gasoline you would actually only be paying $0.03 (3 cents) per gallon of fuel vapor.

How can you convert 1 gallon of liquid gasoline fuel into 160 gallons of gasoline vapor and increase your fuel supply by 16,000%? There are two known and proven ways to convert liquid gasoline into fuel vapor. One is to heat the liquid fuel before it enters the engine. The other is using ultrasonic nebulizer technology.

If liquid fuel is heated to a temperature of 450 degrees F, the fuel is fractionalized by catalytic cracking and converted to smaller light molecular hydrocarbons, methane and methanol. Where can you get this kind of heat in order to fractionalize liquid fuel? Manifolds and exhaust pipes can reach temperatures of 500°F to 1000°F.

It is a well documented fact that air pollution from internal combustion engines is caused by unburned carbon fuel. Today, all gasoline powered vehicles burn only finely divided particles or droplets that are sprayed from the carburetor or fuel injectors, into the engine cylinders. This is a very wasteful process of converting gasoline or diesel to energy. 20-30 % efficiency at best. Converting liquid gasoline to a gasoline vapors will easily give 5 times the mpg and near zero emissions.

In the old days engines ran very lean as demonstrated by the fuel needle valve. In the old days just 1 tiny needle valve did the work of 6 to 8 fuel injectors. In the old days all engines ran on a much leaner amount of (less) fuel.

All internal combustion engines were made to run on highly combustible vapor, not liquid. It is well known that fuel-lean running improves the fuel efficiency of all vehicles. In the old days, under cruising conditions, the carburetor engines always ran lean – about 15% excess air. In the old days liquid fuel was reduced (made leaner) to finely divided particles or droplets before they enter the combustion chamber above the pistons. The carburetors reduced the liquid fuel into a very lean fuel mist before the fuel entered the combustion chamber above the pistons. Very high gas mileage is achieved by simply reducing liquid fuel into what all combustion engine need – gas vapor.

Vapor burns much cleaner than gasoline and has a higher octane rating. A lean running engine (ie, an engine using more air than fuel) has a cooler combustion process than the typical ECM engine with a preset (never deviating) chemically correct mixture of 14.6 air : 1 fuel. Running cooler is also better for the engines. Cooler running engines means a reduction in heat damage and failure.

In the early 1930s, Charles Nelson Pogue equipped a Ford V8 coupe with a vapor carburetor he designed and built and got over 200 MPG. He drove the V8 Ford from Winnipeg, Manitoba Canada to Vancouver B.C. Canada. He traveled 1879.5 miles on just 14.5 gallons of gasoline (the entire distance on just 3/4 of a 20 gallon tank of fuel) A standard carburetor used 106.5 gallons (or five, 20 gallon tanks of fuel) on the same trip.

In 1977, Tom Ogle demonstrated a 351 ci. Ford getting over 100 miles per gallon. He used a multiple fuel vaporizing system that had a 3 gallon tank. His system used heat to vaporize the liquid fuel. He received patent number 4,177,779 on Dec. 11, 1979, which described “A fuel economy system for an internal combustion engine which, when installed in a motor vehicle, obviates the need for a conventional carburetor, fuel pump and gasoline tank. The system operates by using the engine vacuum to draw fuel vapors from a vapor tank through a vapor conduit to a vapor equalizer which is positioned directly over the intake manifold of the engine.”

An ultrasonic nebulizer can also convert liquid fuel into a vapor. Liquids such as water acids, salt solutions, fuels, acetones, ketones, etc., can be atomized (to convert a substance into very fine particles or droplets). Ultrasonic atomizing is carried out by focusing ultrasonic energy onto a liquid surface and by scattering liquid particles by the energy.

Vapor volume of a liquid is the number of cubic feet of vapor resulting from the complete evaporation of the liquid. The vapor volume depends on parameters of density, temperature, pressure and molecular weight which is affected by the variety of formulas for gasoline that is comprised of a wide range of hydrocarbons.

Using a common industrial formula: one liquid gallon = [(8.31) x (SG) x (387 cu ft)] / (MW) Where:

8.31 = pounds in a gallon of water

SG = specific gravity of liquid being vaporized

387 = At standard conditions, one pound-molecular weight of a material will evaporate to fill 387 cubic feet of space.

MW= molecular weight of liquid being vaporized

Using the approximate gasoline constants:

One liquid gallon of gasoline = [(8.31 pounds in a gallon of water) x (.70 approx. specific gravity of gasoline) x (387 cu ft)] / (105 molecular weight of average gasoline) = 21.4 cubic feet of vapor volume. There is 7.481 U.S. gallons in one cubic foot. Therefore one liquid gallon of gasoline = (21.4 cubic feet) x (7.481) = 160.4 gallons of saturated gasoline vapor. The vapor volume will vary based on the specific formulation of gasoline, pressure, and temperature. Ultrasonic nebulizer technology makes it possible to convert 1 gallon of gasoline into 160 gallons of highly combustible fuel.

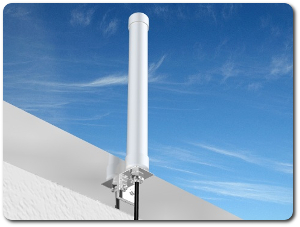

How an ultrasonic nebulizer works to convert a liquid to gas.

Using an ultrasonic nebulizer, liquids in a vessel (such as a fuel tank) sit on top of a vibrating element. and a high intensity ultrasound is omitted. As waves move through the liquid, the liquid will begin to be pushed upward, making a small fountain. Off the surface of this fountain small particles will begin to float above the liquid and appear like smoke. This smoke like appearance is actually very fine vapor. If gasoline was used in this process the small particles that would appear like smoke would be very fine gas vapor. To move the very fine particles a small air flow/gas or vacuum is needed – like a small fuel pump or the vacuum that exists in all combustion engines.

Is the ultrasonic nebulizer technology to convert liquid gasoline into a more abundant (160 times more) vapor gas safe to use? A fog machine reveals that it is safe as a fog machine is a device which emits a dense vapour that appears similar to fog. This artificial fog is most commonly used in professional entertainment applications. Typically, fog is created by vapourizing proprietary water and glycol-based or glycerine-based fluids or through the atomization of mineral oil. Mineral oil is liquid petroleum which is a liquid by-product of the distillation of petroleum to produce gasoline and other petroleum based products from crude oil. If a fog machine can safely and effectively atomize mineral oil – a by-product of oil – then a similar device like an ultrasonic nebulizer can also safely and effectively atomize 1 gallon of gasoline to produce 160 gallons of gasoline vapor.

Who said the reason for high gas prices was because the World is running out of oil? George W. Bush did on March 5th 2008 ~ “We gotta get off oil, American has got to change its habits,”.. “It should be obvious to all, demand has outstripped supply, which makes prices go up.”

President Obama asked Americans in an Oval Office address to accept that the United States is running out of places to drill for oil. President Obama said in his first live televised address from the Oval Office that: “For decades we have known the days of cheap and accessible oil were numbered. For decades we’ve talked and talked about the need to end America’s century long addiction to fossil fuels and for decades we have failed to act with the sense of urgency that this challenge requires.”

The US government’s claim that the World is running out of oil was made to drive up the prices. Higher gas prices means bigger profits for US oil companies. Just look at the Fortune 500 list – Exxon Mobil, Chevron and ConocoPhillips are number 2, 3 and 4 respectively. We are not running out of oil we are being fleeced by the oil companies. With the technology readily available today – specifically liquid to gas vapor technology – they are also wasting oil.

“Governments and the national oil companies are obviously controlling about ninety per cent of the assets. Oil remains fundamentally a government business. While many regions of the world offer great oil opportunities, the Middle East with two thirds of the world’s oil and the lowest cost, is still where the prize ultimately lies, even though companies are anxious for greater access there, progress continues to be slow.” ~ Dick Cheney speech at the Institute of Petroleum Autumn lunch, 1999.

If you were to incorporate this vaporizing technology into the manufacturing of a new ultra fuel efficient car those cars could travel a hundred time farther on one gallon of liquid fuel. On average the fuel efficiency of most cars on the road today is approximately 20 mpg. 20 mpg x liquid to vapor conversion factor of 160 = 3200 mpg.

Short URL: https://presscore.ca/news/?p=2627

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

Please take a moment to sign a petition to

Please take a moment to sign a petition to

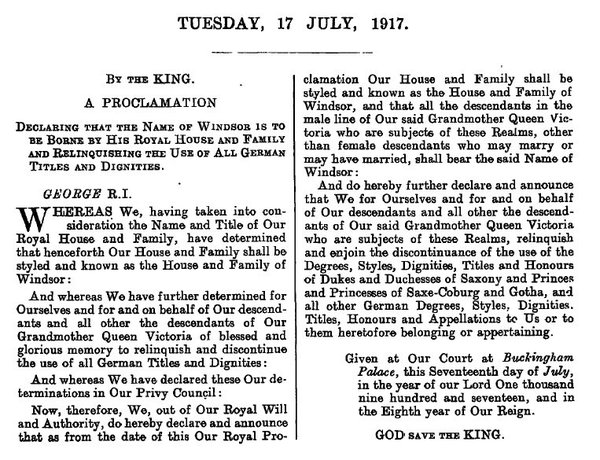

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online  Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Portable gas generator vacuum liquid to gas fuel system made in 2005, © Paul W Kincaid

Here is an easy way to increase the fuel economy of all portable gas generators. It uses a vacuum line and a filtered air intake line to draw gas vapor from the liquid fuel. Gas vapor generation is enhanced by adding a circulation hose to the fuel petcock. The engine vacuum will draw fuel out through the fuel petcock and into the attached circulation hose and spray out into the top of the tank. The only thing you will need to install on the vacuum line that feeds the vapor to the gas combustion engine is a marine fuel primer pump – shown below. Pump the primer several time to draw enough air into the gas tank to generate enough gas vapor to start the engine. Once the engine fires engine vacuum will take over.

All portable gas generators wastes a lot of fuel. Liquid fuel is simply sprayed into the cylinders which isn’t a very efficient use of the very expensive fuel. Add the fact that the CO2 output of these generators are much higher than automobiles. You cannot run a gas generator indoors because the levels of CO2 are extremely high and it will kill you in a very short period of time.

The above described system to generate gas vapor from liquid fuel drastically lowers the emissions of the portable gas generator. In the process it can potentially increase the fuel efficiency by at least 10 fold. Less fuel will be wasted and the portable gas generators can run a lot longer. If you gas generator now runs 4 hours on a tank of fuel you could run it for 40 hours using the same amount of liquid fuel.

If 1 gallon of liquid fuel equals 160 gallons of gas vapor how long do you think a portable gas generator will run if you feed it only gas vapor? Potentially 160 times longer. If your liquid to gas vapor system runs at full efficiency you could essentially run your gas generator for 640 hours (160:1 x 4) or 26.6 days. Even if you only get 10 times more running time, your fuel costs has decreased by 1000%.

If you don’t want to drill holes into the tank of your new and expensive gas generator you can convert your gas generator to a gas vapor system simply by drilling and setting the ports into the gas cap or a replacement gas cap that you can buy from the manufacturer. This way you can experiment with the above gas vapor fuel system and still have an original gas generator, if you mess up.

It takes two to five barrels of fresh drinking water to produce every barrel of the toxic Alberta tar sludge they call oil. About two tons of oil sands are required to produce one barrel of tar sludge. …. All these processes take large amounts of energy and water, while emitting very high amounts of CO2.

Approximately 1.0–1.25 gigajoules (280–350 kWh) of energy is needed to extract just a barrel of tar sludge and refine it into a toxic imitation crude. Alberta produces about 1.8 million barrels of tar sludge (they market it as crude oil) per day. That means is consumes as much as 630 million kWh per day of energy. The average household in America consumes 10656 kWh “per year”, according to the US Department of Energy.

As of 2006, most of the Alberta Tar Sludge is produced by burning natural gas. However, since natural gas production in Alberta peaked in 2001 the energy cost to produce each barrel has since increased. Since then a good portion of all Alberta Tar Sludge produced is now used to strip mine, truck, process and refine more Alberta Tar Sludge. How many barrels of Alberta tar sludge is used each day just for excavating and trucking the sand from the open strip mining pits? The Caterpillar 797 mining truck consumes an average of 65 gallons/hr … with a fuel economy rating of just 0.3 mpg. How many Caterpillar mining trucks are in service at the Alberta Tar Sand strip mining operations?

How about the O&K RH400 excavator shown in the picture above. It has a fuel tank capacity of 4230 US gal (the same amount of fuel to fill 211 cars with a 20 gallon gas tank). How long does that astonishing amount of fuel last? Add the cost of destroying the environment, the cost of storage, marketing, distribution and transportation and you get how much return? Hardly worth mining it at all when so much energy, fuel, and money is consumed to produce just 1 barrel of toxic environmentally unfriendly Alberta Tar Sludge – – unless you simply jack up the price of gas at the pumps to over $5.5 a gallon in order to make any kind of profit.

At least 90% of the fresh water used in the oil sands ends up in tailing lakes so toxic that propane cannons and floating scarecrows are used to keep ducks from landing in them.

A 2003 report concluded that “an accident related to the failure of one of the oil sands tailings ponds could have catastrophic impact in the aquatic ecosystem of the Mackenzie River Basin due to the size of these lakes and their proximity to the Athabasca River.”

Processing the oil sands uses up enough natural gas in one day to heat 3 million homes in Canada.

The toxic tailing lakes are considered one of the largest human-made structures in the world. The toxic lakes in Northern Alberta span 50 square kilometers and can be seen from space.

Producing a barrel of oil from the oil sands produces three times more greenhouse gas emissions than a barrel of conventional oil. By 2020 the oil sands operations will release twice the amount produced currently by all the cars and trucks in Canada.

If the Canadian government metered the fresh water used in the tar sand processing, like they do every other homeowner and business throughout Canada, the Alberta Tar Sludge strip mining operations would not exist.

In the FEMA_emergency_gassifer.pdf file mentioned in the above comment, page 13 FEMA states:

“The use of wood to provide heat is as old as mankind; but by burning the wood we only utilize about one-third of its energy. Two-thirds is lost into the environment with the smoke. Gasification is a method of collecting the smoke and its combustible components.

FEMA is inadvertently disclosing the technology that would make all wood stove 60% more energy efficient. Anyone in the wood stove manufacturing business could use this FEMA disclosure to make their stoves more energy efficient and even modify the manufacturing of their stoves so that the smoke and combustible material can be collected and used to power a gas generator and light every home and business in the United States.

Gasification is a process that converts organic or fossil based carbonaceous materials (i.e. wood) into carbon monoxide, hydrogen and carbon dioxide. By reacting the wood at high temperatures with a controlled amount of oxygen and/or steam the resulting gas mixture (called syngas) is produced. This syngas can then be used as a fuel. The power derived from gasification of biomass and combustion of the resultant gas is considered to be a source of renewable energy because wood is renewable.

Syngas is potentially more efficient than direct combustion of the original fuel. Syngas may be burned directly in gas engines.

Even the US government knows that gas vapor and not liquid fuel is what runs all internal combustion engines.

FEMA – “All internal combustion engines actually run on vapor, not liquid. The liquid fuels used by gasoline engines are vaporized before they enter the combustion chamber above the pistons.”

“In diesel engines, the fuel is sprayed into the combustion chamber as fine droplets which burn as they vaporize.

Even FEMA – a US government agency – has a contingency plan for when oil is in short supply. In March 1989 FEMA released this report – “Construction of a Simplified Wood Gas Generator for Fueling Internal Combustion Engines in a Petroleum Emergency” http://www.woodgas.net/files/FEMA_emergency_gassifer.pdf

“The purpose of this report is to develop detailed, illustrated instructions for the fabrication, installation, and operation of a biomass gasifier unit (i.e., a ‘producer gas’ generator, also called a “wood gas’ generator) that is capable of providing emergency fuel for vehicles, such as tractors and trucks, in the event that normal petroleum sources were severely disrupted for an extended period of time. These instructions have been prepared as a manual for use by any mechanic who is reasonably proficient in metal fabrication or engine repair. This report attempts to preserve the knowledge about wood gasification that was put into practical use during World War II. Detailed, step-by-step fabrication procedures are presented for a simplified version of the World War II, Embowered wood gas generator.”

Why did Canada commit to the US war of aggression against Libya if Canada is claiming to be an oil producing nation? The US. No other country but the United States, is stupid enough to buy Canadian Tar Sand and pour it in their very expensive engines. Canadian Prime Minister Stephen Harper committed war crimes against Libya, its elected leader and its civilian population to appease Canada’s number 1 customer of this over priced and very toxic tar sludge.

Above image is from the Alberta government website – http://www.energy.alberta.ca/OilSands/1719.asp What do you see? Dirt or oil? Sand truck or oil tanker?

Tar sludge is a hazardous waste that is a by-product of the tar cooking process. It is a dark, sticky substance that poses serious threats to human health, environmental standards and worker safety. That is exactly what Canadian oil is – tar sludge. The stripped mined tar sands of Alberta is cooked, using fresh drinking water, to purposely make this very toxic tar sludge. They then refine this very toxic by-product using more toxic solvents to dissolve away the substance of interest – counterfeit oil.

The true test as to whether or not Alberta Tar sand is oil or not is easily demonstrated by the fact that natural petroleum will burn straight from the ground. Alberta Tar Sand will not. Oil tankers and oil platforms can explode with just a small spark. You can spray an Alberta Tar sand strip mine with a flame thrower and it won’t explode. If you smoke on or near an oil rig you can cause a catastrophic explosion and fire. Strip miners at the Alberta Tar sand pits can smoke and even throw their lite cigarette butts on the exposed Alberta Tar Sand and it won’t cause an explosion or instantaneous fire.

If Iran had no oil, do you really think the United States government would be imposing sanctions against Iran and be planning for and preparing for yet another unprovoked war. Iran has the second largest oil reserves in the world, and the third largest exporter of it. Venezuela is the largest now that Saudi Arabia has depleted its oil reserves – according to a major Saudi Arabia oil company – oil in the country will be depleted by 2013 based on current worldwide consumption.

It was because of oil that the US attacked Afghanistan – to build the Trans Afghan Pipeline. It was because of oil that the US attacked Iraq. It was because of oil the US attacked Libya. Oil reserves in Libya are the largest in Africa and the eighth largest in the world with 46.4 billion barrels as of 2010. It is because of oil that the US sent mercenaries to Syria to cause an uprising. In 2010, Syria produced around 385000 barrels per day of crude oil.

Would the US spend $trillions on 5 wars of aggression against the major oil producing nations if there was a way to increase the supply of oil 160 fold? Do you really think gas prices would be so high if the technology to convert 1 gallon of liquid gasoline to 160 gallons of gas vapor was being utilized today?

The Canadian government doesn’t want this technology to get out. Canada needs oil demand to be high (or a false claim of peak oil) in order to make money off a product that is millions of years away from being oil. In Canada, the only reason why gas prices are higher than anywhere else is because of the fact that Canada doesn’t have oil. Canada has tons of tar saturated sand that they are strip mining, adding billions of gallons of steam and water to, in an attempt to deceive the World market that Canada has oil. It is very expensive to strip mine tar and synthesize it in order to make it look like oil. You need a lot more people to work a strip mine than an oil rig. The workforce alone requires a minimal market price for this tar crap. Add any amount of thinning solvents to the mixture and you need to jack up the market price some more. Making sand into an unconventional (fabricated) oil costs a lot of money and this over cost is reflected at the gas pumps.

The FuelReducer mpg+, http://www.fuelreducer.com, performs the same function as the carburetor needle valve – allowing a constant, calibrated, lower flow rate. Like the needle valve the FuelReducer mpg+ has a much smaller orifice than the vehicle’s fuel line. The needle valve only allows a lean flow rate of fuel to enter the combustion engine. As does the FuelReducer mpg+, which has been sold throughout Canada and the US since 2006.

Why haven’t you heard about the technology that has proven that much higher gas mileage is possible? The oil industry and government have been intentionally keeping you in the dark. The oil industry stands to lose money if the people knew about this technology. Government would lose tax revenue too. So they cover up this technology. If they can’t prevent the word from getting out they launch attack campaigns against the inventor using full page newspaper ads and websites to claim, without proof, without ever testing the technology, without ever buying and using the technology, that these new fuel saving devices are all a scam and must be avoided. They claim fuel saving and fuel eliminating technology are all: “Just another gimmick to take your money.”. If that is the case then everything that has ever been sold is a scam too as everything that is sold takes money from you and gives it to the vendor. Selling a new car is also a scam because GM, Ford, Chrysler, Honda, and Toyota all design a new model each year, as a gimmick, to get you to buy their product wherein they take your money. After all a gimmick is defined as a unique or quirky special feature that makes something “stand out” from its contemporaries.

How many times have you bought stocks and ended up losing it all? Stocks are a scam in that they all take your money when they fail. All stocks eventually fail so the banks are selling you, the consumer, a product they know is defective and will fail just to take your hard earned money from you. Now that is truly a scam.

The ones who are claiming that this new technology is a fraud are the fraudsters. A fraud is an intentional deception made for personal gain or to damage another individual. The oil industry and government are committing fraud by intentionally deceiving the public and causing harm to the inventor. The deception is the false claim that these devices don’t work. A claim they make despite the fact that they have never even bought, tested or used any of this technology. An intentional deceptive and unfounded claim that is based purely on conjecture and perpetrated for their own personal financial gain.