Generate a lifetime supply of natural gas without very toxic and life threatening fracking.

Getting Off Oil, World news Saturday, May 30th, 2015There is a much easier, cheaper and environmentally friendly way to produce natural gas from water without poisoning our water supply with very toxic fracking chemicals. No toxic sulfuric acid chemicals whatsoever are required. No drilling is required. No earthquakes are induced. No poisonous evaporation ponds are ever created. Natural gas can be produced at home using electrolysis. Electrolysis of water produces ultra clean hydrogen gas fuel using no toxic chemicals whatsoever and very little energy.

Unlike shale (dirt) fracking, electrolysis of water creates no pollution – doesn’t contaminate the water, the land or the air. Unlike dirt fracking, electrolysis of water doesn’t trigger earthquakes nor poison our finite supply of drinking water. Anyone can make their own natural gas using electrolysis.

The natural gas known as hydrogen can be generated from water – tap water, sea water, drain water, dish water, any water. Water (H2O) can easily be split (fissioned) into zero emission hydrogen gas using a simple method called electrolysis.

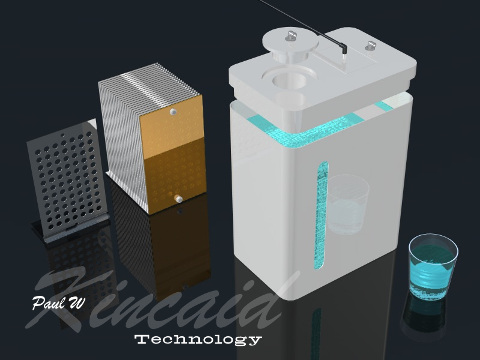

Video created by the editor of PRESS Core, Paul W Kincaid, in 2006 demonstrating electrolysis of water. Just 4.5 volts was used to split water (fission) into its hydrogen and oxygen gas. No heat is applied to split the bond between the hydrogen and oxygen atoms.

In electrolysis of water a very small electrical current is passed between electrodes submerged in water. Natural gas production from electrolysis of water will begin with a minimum of 1.2 volts and will increase in rate as the voltage is increased. Hydrogen gas accumulates at the cathode (negative electrode) and oxygen gas at the anode (positive electrode).

Sources of electrical current that can be used in the electrolysis of water – car battery (12 volts), solar panel (5-15 watts), flashlight battery (1.5 volts), cell phone battery (3.7 volts).

12 volts (just 10% or 1/10 the electrical power needed to power the toxic fluorescent lights which requires 120 volts to operate) would produce more than enough hydrogen gas fuel to power a gas combustion engine like a portable electrical power generator. The hydrogen gas from water can also be used to fuel gas stoves, gas fireplaces, gas barbecues and gas home heating furnaces.

A hydrogen gas fuel cell can be mass produced for under $100. For home applications 12 volts is all that you need to produce natural gas from dish water, drain water, tap water or collected rain water. 12 volt power supplies are already mass produced and sold at major department stores like Canadian Tire, Walmart, or Home Depot. You can make your own using mass produced store bought containers and electrical supplies. How? Just Google “electrolysis of water” or “hydrogen fuel cells” or Stanley Myers. Stanley Myers powered a dune buggy on water alone. A Japanese company Genepax did the same thing in 2008 – ran a car on nothing but water.

Today Japan is producing hydrogen fueled cars – the Honda FCX Clarity. Combine the technology of Genepax with the technology of the Honda FCX Clarity and you have a full production vehicle that uses no gasoline. No gasoline combustion means zero emissions. Zero emissions means no smog, no more respiratory disease and no global warming hoax.

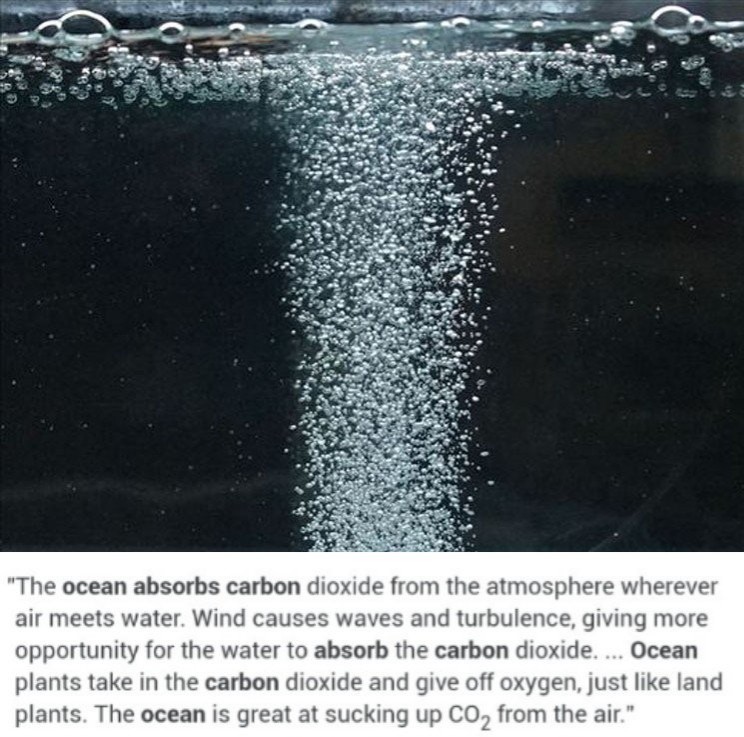

The best water to use to produce hydrogen gas using electrolysis of water is sea water. Water covers 70.9% of the Earth’s surface. Oceans hold 97% of surface water. Out of all the water on Earth, only 2.75 percent is fresh water, including 2.05 percent frozen in glaciers, 0.68 percent as groundwater and 0.011 percent of it as surface water in lakes and rivers. That means as much as 97% of the water on Earth is sea (salt) water and is available to us to use as a fuel source for a very, very long time.

Short URL: https://presscore.ca/news/?p=9527

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

Please take a moment to sign a petition to

Please take a moment to sign a petition to

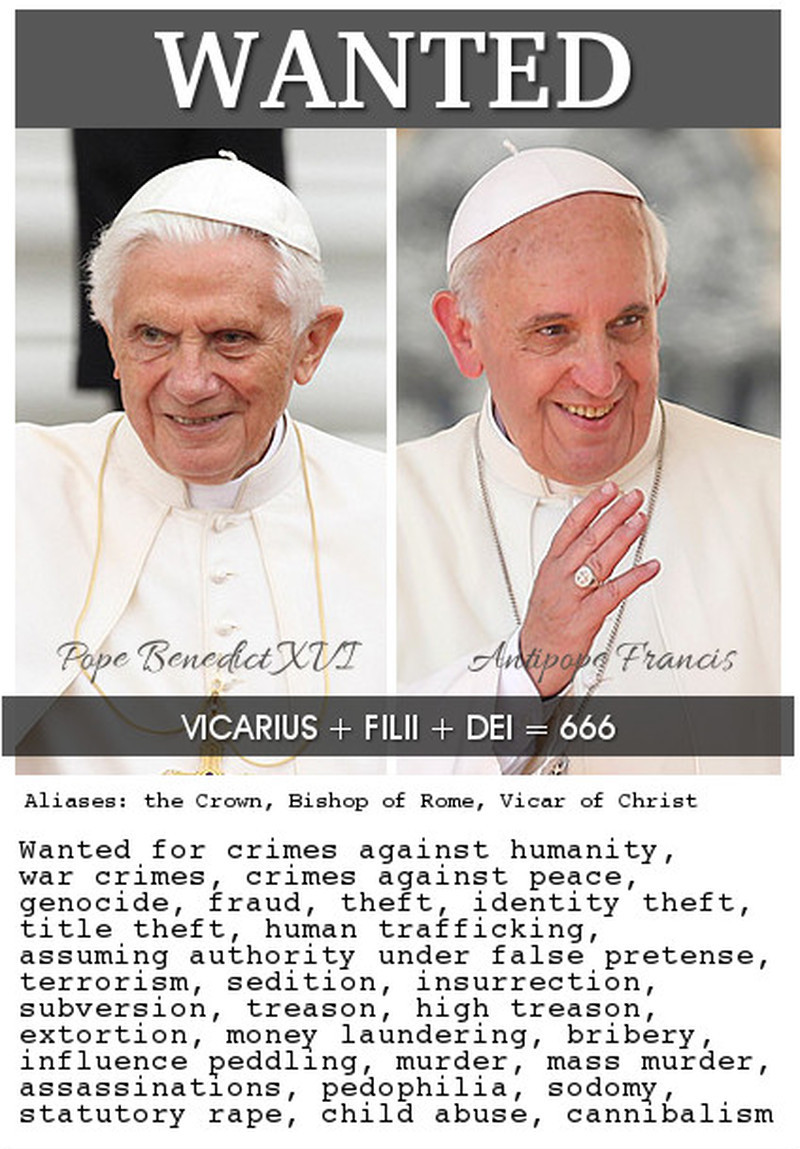

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online  Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

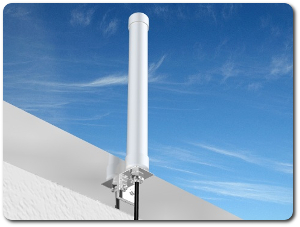

H2O fuel cell design using mass produced PVC drain pipe and their matching end caps.

In order to have current flow from the atmosphere into the H2O fuel cell the fuel cell must be grounded. The black wire coming out of the bottom electrical box is a ground wire. In order for the antenna to receive EM waves a good ground is necessary. Just ask any ham radio operator.

In this H2O fuel cell design all wiring is housed in the bottom of the PVC tubing to allow only natural gas produced from the water to vent from a centered single fitting on the top cap. More than one hole on the top could lead to unwanted gas leakage. For safety applications the top cap also acts as a blow off cap in case too much gas pressure builds up inside the H2O fuel cell.

Warning !!!! A lot of pressure can build up very quickly inside a H2O fuel cell. Enough to blow the fuel cell apart. I know I had 2 blow up on me when I first started experimenting with fuel cells in 2006. Be careful. Make sure pressure is properly released to prevent a blow out. Never completely seal the top cap of the fuel cell. Allow it to pop off under excessive pressure or install of pressure release value that is rated to release pressure that is lower than the PVC pipe’s Minimum Burst Pressure. You don’t need to build a high pressure fuel cell. Carburetor engines needed only a max of 15 psi of fuel pressure. Fuel injection cars needs more but no more than 60 psi of fuel pressure to operate. For use at home, to fuel your gas furnace, gas fireplace, gas barbecue, gas electrical power generator or gas cooking stove you don’t need high gas pressure like cars and trucks need and that is why fuel cells for home applications are much smaller and need very little energy to split (fission) water and produce a clean, environmentally friendly, hydrogen fuel.

Antenna powered hydrogen from water fuel cell design by © Paul W Kincaid.

If Tesla powered a Pierce Arrow automobile (weighed 4710 lbs) and Moray powered 35 – 100 watts light bulbs (3500 watts) and a 1200-watt iron simultaneously (4700 watts total power) using an antenna then an antenna can also be used to harness enough energy to split water into its hydrogen and oxygen gases and create hydrogen fuel. The small solar panel on the image above activates a MOSFET transistor so that energy can flow from the atmosphere into the fuel cell and split the water.

A transistor is a semiconductor device used to amplify and switch electronic signals and electrical power. A voltage or current applied to one pair of the transistor’s terminals changes the current through another pair of terminals. Because the controlled (output) power can be higher than the controlling (input) power, a transistor can amplify a signal.

An antenna (or aerial) is an electrical device which converts a signal (radio waves) into electric power, and vice versa. When an antenna receives a signal, it converts that signal into an electric current. To transmit, the process is reversed and the antenna converts the electrical current into a signal. For the above designed fuel cell an antenna is utilized to only receive a signal and convert the signal into electric power and split the water into a hydrogen fuel.

The essential usefulness of a transistor comes from its ability to use a small signal (a small solar panel) applied between one pair of its terminals to control a much larger signal (200 volts positive per meter square) at another pair of terminals. This property is called gain.

By way of analogy, a transistor acts like a flow valve hooked to a water faucet. It is much like turning a valve to control a supply of water. The transistor allows electric current to flow freely from the antenna through the fuel cell.