Free life time supply of renewable natural gas for your homes and cottages

Getting Off Oil, World news Sunday, February 23rd, 2014

recycling human waste into a free year round supply of natural gas

You and millions of people in Canada, the United States, South America, Africa, Australia, Europe and Asia can generate a free life time supply of renewable and unmetered natural gas for your homes and cottages. You can very easily produce your own life time supply of environmentally friendly natural gas in your own back yard and fuel your gas furnace, gas fireplace, gas electrical power generator, gas stove, or other gas fueled appliances using your existing septic tank. The free natural gas fuel called biogas (CH4 – methane) is already being generated 24/7, 365 days a year and for the rest of your life by your existing septic tank. You only need to enhance its production by adding a catalyst – a small amount of natural enzymes like brewers yeast – that will enhance the rate of chemical reaction and break down of the biomass (organic matter) in the septic tank into a free natural gas fuel. In order to use this free life time supply of natural gas you will need to connect a natural gas collector to your septic tank system. In a matter of hours you can build your very own natural gas well and start using your free life time supply of unmetered natural gas fuel.

free natural gas and battery power from your septic tank

You can build your very own natural gas well and start producing and collecting your year round free supply of natural gas simply by adding a biogas collector to your exiting septic system. A biogas collector is placed on top of your existing septic tank to collect and store the natural gas that is being produced naturally and perpetually by your septic tank. You can use any large “airtight” plastic or metal container (even a plastic fuel tank or furnace oil tank) as your biogas collector. Join your septic tank to the collector using mass produced flexible plumbing tubing. Run a length of pipe from the top of the collector to just above ground height. Attach a gas regulator value (like the ones used for barbecues) and a safety blow off valve to the top of the pipe to control the gas flow or shut it off and on. Fill in with dirt and let mother nature generate a “lifetime supply” of free environmentally friendly natural gas.

Bench houses the electrical wiring, voltage regulator & power inverter

Well functions as a surface maintenance conduit and outdoor fire pit

Build a stone well flower bed or lay a concrete culvert directly above the biogas collector and use it as a natural gas well head and provide easy access and maintenance to your natural gas well surface piping.

Biogas is a gas produced by the biological breakdown of organic matter in the absence of oxygen. Organic waste such as dead plant and animal material, animal feces, and kitchen waste can be converted into a gaseous fuel called biogas. Biogas originates from biogenic material and is a type of bio fuel.

Biogas is produced by the anaerobic digestion or fermentation of biodegradable materials such as biomass, manure, sewage, municipal waste, green waste, plant material, and crops.

The gases methane, hydrogen, and carbon monoxide (CO) produced is combustible. This energy release allows biogas to be used as a fuel. Biogas can be used as a fuel in any country for any heating purpose, such as home heating and cooking. It can also be used in anaerobic digesters where it is typically used in a gas generator to convert the energy in the gas into electricity. Biogas can even be compressed, much like natural gas, and used to power your motor vehicles.

Rural dwellers from around the World can reduce their fuel and home heating and electrical power costs simply by collecting, storing and burning the biogas that is created naturally in their septic tanks. This free biogas can fuel a gas furnace, gas fireplace, gas generator, or other gas fueled appliances.

Using biogas generated naturally from septic tanks and manure anabolic digestion has an added ecological benefit too. Burning biogas can help reduce global climate change. Normally, septic sewage and manure that is left to decompose releases two main gases that contributes to global climate change: nitrogen dioxide and methane. Nitrogen dioxide (NO2) and methane both warms the atmosphere. By converting septic sewage and manure into a methane biogas fuel via anaerobic digestion, the millions of cows in the United States would be able to produce one hundred billion kilowatt hours of electricity, enough to power millions of homes across the United States. Furthermore, by using manure as a methane biogas fuel instead of letting it decompose, we would be able to reduce global warming gases by ninety-nine million metric tons. There are over 300 million people in the United States. They could potentially produce 300 times more electrical power than cows or 3 trillion kilowatt hours of electricity – enough to power every home in the United States.

The key to generating biogas through anabolic digestion in a septic tank is to remove as much excess liquid waste from the septic tank as possible. The easiest step to take to insure the septic tank isn’t flooded is to use less and waste less water. Too much water will reduce the biogas generation.

One way to ensure greater biogas production is to periodically pump as much of the waste water (sewage slurry) from the tank, as possible. Incorporating a sewage pump – a type of sump pump that is intended for use with waste water – into your septic tank biogas generating system will increase the biogas production. As the pump (only should be done periodically) removes excessive waste water from the top of the solid sewage it will also create a vacuum in the tank. That is an added benefit as biogas is produced by the biological breakdown of organic matter in the “absence of oxygen” – in other words in a vacuum. Where do you pump the excess waste water? To your pre-existing septic bed (also called a drain field). The liquid waste or effluent already flows out of the tank and evenly distributed into the soil through the septic bed.

Never pour chemical household or septic tank cleaners like CLR (contains Water, Lactic Acid (OSHA Hazard), Gluconic Acid, Lauryldimethyl Hydroxysulaine, and Propylene Glycol Normal Butyl Ether (OSHA Hazard) into your septic tank system if you want to produce your very own life time supply of unmetered natural gas. CLR kills the microorganism and enzymes that naturally and perpetually breaks down the biomass in your septic tank into a free life time supply of natural gas. Chemicals like CLR are not environmentally friendly. They not only kill the microorganism and enzymes in your septic tank system, which are needed to produce natural gas by breaking down biomass, they kill all of the microorganism and enzymes in the soil above rendering your land dead. If you ever want to grow your own food in your backyard or farm fields CLR will kill the soil and you will not be able to grow any nutrient rich fruits or vegetables as the fruit and vegetables get their nutrients from the soil.

Related Article:

Cities and towns around the World flowing with billions of liters of free renewable fuel

Free electrical energy from your own septic tank battery

You can also use your septic tank as an earth battery and generate electrical power. An Earth battery is a pair of electrodes made of two dissimilar metals, such as iron and copper, which are buried in the soil or immersed in the sea (salt) or other acidic liquid (lemon juice, vinegar, sulfuric acid, uric acid etc.,). Earth batteries act as water activated batteries and if the plates are sufficiently far apart, they can tap electrical currents. Earth batteries have been used for centuries, but it more recent times they were used in the 1800’s to power telegraph stations.

Daniel Drawbaugh received U.S. Patent 211,322 for an Earth battery for electric clocks (with several improvements in the art of Earth batteries). Another early patent was obtained by Emil Jahr U.S. Patent 690,151 Method of utilizing electrical Earth currents). In 1875, James C. Bryan received U.S. Patent 160,152 for his Earth Battery. In 1885, George Dieckmann, received US patent U.S. Patent 329,724 for his Electric Earth battery. In 1898, Nathan Stubblefield received U.S. Patent 600,457 for his electrolytic coil battery, which was a combination of an earth battery and a solenoid.

Most batteries sold and bought today work as a result of a chemical reaction that occurs inside the batteries. Car batteries makes us of this chemical reaction to provide electrical power for your car’s electrical systems – lights, radio etc. Sulfuric acid is used and combined with water to produce electrolytes. Electrolytes is required to produce a chemical reaction. Electrolytes can be produced without using the extremely corrosive and highly toxic sulfuric acid. Lemon juice, vinegar and our excrements that are flushed down the toilet and into septic tanks can also be used to produce electrolytes.

The lemon battery that some of us made for a school project is similar to the first electrical battery invented in 1800 by Alessandro Volta, who used brine (salt water) instead of lemon juice. The lemon battery is described in textbooks in order to illustrate the type of chemical reaction (oxidation-reduction) that occurs in batteries. The “acidic” juice inside the lemon that causes a chemical reaction is called an electrolyte.

When zinc (or iron) and copper metal plates or rods are immersed in an electrolyte, energy can be obtained and generated. The stronger electrical currents flow from south to north. This phenomenon possesses a considerable uniformity of current strength and voltage. As the Earth currents flow from south to north, electrodes are best positioned, beginning in the south and ending in the north, to increase the voltage at as large a distance as possible.

It has been found that all the common metals behave relatively similarly. The two spaced electrodes (metal plates or rods), having a load in an external circuit connected between them, are disposed in an electrical medium, and energy is imparted to the medium in such manner that “free electrons” in the medium are excited. The free electrons then flow into one electrode to a greater degree than in the other electrode, thereby causing electric current to flow in the external circuit through the load. The current flows from that plate whose position in the electropotential series is near the negative end . The current produced is highest when the two metals are most widely separated from each other in the electropotential series, and when the material nearer the positive end is to the north, while that at the negative end is towards the south. The plates, one copper and another iron or carbon, are connected above ground by means of a wire with as little resistance as possible. In such an arrangement, the electrodes are not appreciably chemically corroded, even when they are in earth saturated with water, and are connected together by a wire for a long time.

Because acidic human waste (uric acid) is created daily and added to the septic tank your septic tank can also be used as a battery and generate free electrical energy for years. All you need to do is what the telegraph company did in the 1800s or what kids do at school to demonstrate electrical power using lemons – immerse a couple of electrodes (thin copper and iron rods or pipes) into the ground and into your uric acid (electrolyte) septic tank and make your own “life long” septic tank battery. If your car’s lead acid battery can store electricity so can your septic tank. Instead of using sulfuric acid that is used in car batteries another acid, uric acid, is used and combined with water to produce electrolytes.

A septic tank battery will never go dead as long as you keep on recharging it simply by going to the bathroom and flushing new electrolytes into it.

Septic tank natural gas fuel cell construction basics

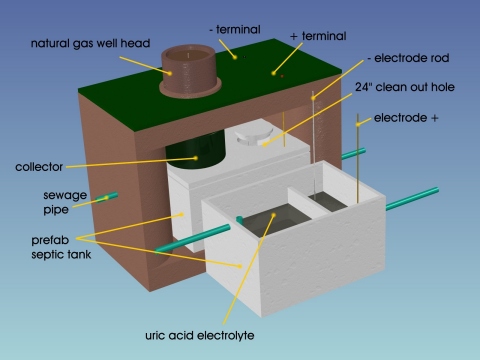

septic tank natural gas fuel cell

Building your own septic tank natural gas fuel cell (battery) is pretty simple because you already have most of the major components. Your septic tank is already laid in the ground and most today look like the image below. Today, most septic tanks are made of prefab concrete. They will most likely have 2 compartments built-in like shown in the image. The larger one is were all of the solid waste settles and the smaller one is mostly liquid waste that eventually drains out into your already laid septic bed. The tank is covered with a concrete slab, shown to scale in the image below. The cover already has 2 – 24″ clean out holes and some also have smaller inspection holes. You will need to excavate the earth away from the top of the septic tank in order to lay the collector on top of your septic tank and affix 2 electrodes into it.

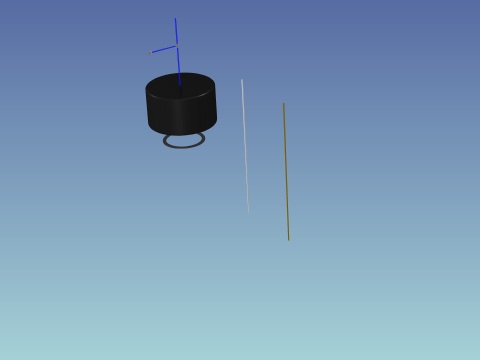

septic tank natural gas fuel cell existing components

There are very few components that you will need to acquire to make your own septic tank natural gas fuel cell – see image below. The most important component that you will need to acquire before you start construction your own natural gas well is the collector. A half sized oil drum, automobile gas tank (new or used) or furnace oil tank will work as will a large air tank (new or used) from an air compressor or tractor trailer air brake system. All are already mass produced and can be bought cheaply from major suppliers or from junk yards.

You will also need a gasket or tube of tar to seal the collector over the clean-out opening of the septic tank cover. You will also need 2 electrodes (metals rods) if you want your septic tank to also function as uric acid battery. They need to be long enough to be completely immersed vertically into the uric acid (electrolyte) inside the septic tank and also stick out from the ground once you fill in and cover the tank and collector with dirt. 1/8″, 1/4″, 3/8″ or 5/16″ solid metal rods can be bought at major hardware chains or metal vendors. Make sure you don’t buy two of the same metal rods. One has to copper and the other iron, zinc or stainless steel.

septic tank natural gas fuel cell required components

To install the natural gas collector requires no drilling into the septic tank cover whatsoever. The natural gas collector is laid on top of the cover directly over one of the 24″ septic tank clean-out openings. You will need to remove the cover from the opening you want to lay the collector over. Warning – it is going to smell really, really bad when you lift that cover.

For illustration purposely I placed the natural gas collector over the opening directly above the larger septic tank compartment. You can place the collector over the other hole. Before laying your collector directly over one of the septic tank clean-out openings make sure you have a small hole on the bottom of the collector. Why? How else is the natural gas going to rise up into the collector. It doesn’t need to be a big hole. The smaller the hole the greater the natural gas pressure inside the collector. If you chose to use an automobile gas tank as your collector place the gas tank upside down over the opening as the gas tank already has a hole where a fuel pump would normally be installed if you installed it in a car or truck. You can then use the gasoline filling hole of the automobile gas tank and attach a natural gas line from it to the surface.

To ensure a proper seal between the septic tank cover and the natural gas collector lay a big enough and thick enough gasket on top of the cover before you lay the collector on top of it. You can also lay a thick bead of tar from a caulking tube if you can’t get the right size gasket that fits around the 24″ clean-out opening. The weight of the earth that you fill in the hole and cover the tank and collector with will keep the collector in place for a long time.

Before you fill everything in you will need to attach fitting to the top of your natural gas collector. What size and type of fittings depends on what you use as you natural gas collector and what you use for tubing. If you use 3/4″ flexible tubing you will need fittings that are made to properly connect with the 3/4″ tubing. If your collector already has pre-drilled holes that are threaded your construction will be much easier. If your collector has no holes on top you will need to commit a little more time and drill and install fittings.

After you attach the proper fittings (the right ones for the tubing you plan on using) to the topside of the natural gas collector you will need to run a length of flexible tubing (i.e. pex gas pipe) from the fitting to the surface. The flexible tubing that runs from the collector to the surface shouldn’t be any bigger than 3/4″. On the surface make sure you attach a shutoff valve to the surface end of your tubing. You don’t want you free natural gas to leak out before you can use it.

Once the construction is completed and everything is properly installed and firmly attached fill in the excavated hole and landscape so that your nosy neighbor(s) and municipal extortionists can’t see what you’ve made.

Let the natural gas collect in the collector for a week or two before you start using it. The natural gas is produced naturally, day and night, 24/7 and 365 days a year and with no interaction from you. More natural gas is produced in the summer months than in the winter months because the outside temperature dictates how much natural gas is produced and how quickly.

Short URL: https://presscore.ca/news/?p=8951

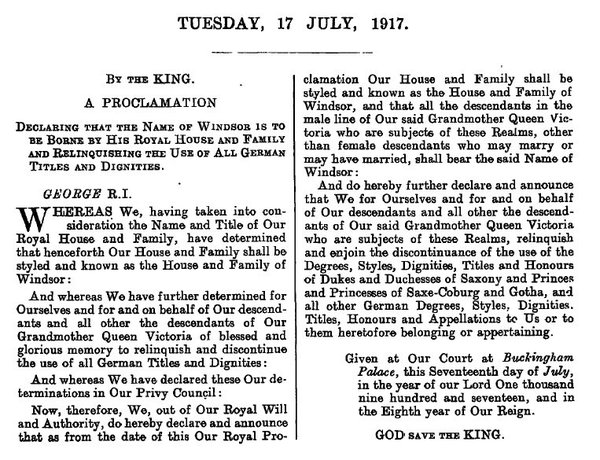

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

Please take a moment to sign a petition to

Please take a moment to sign a petition to

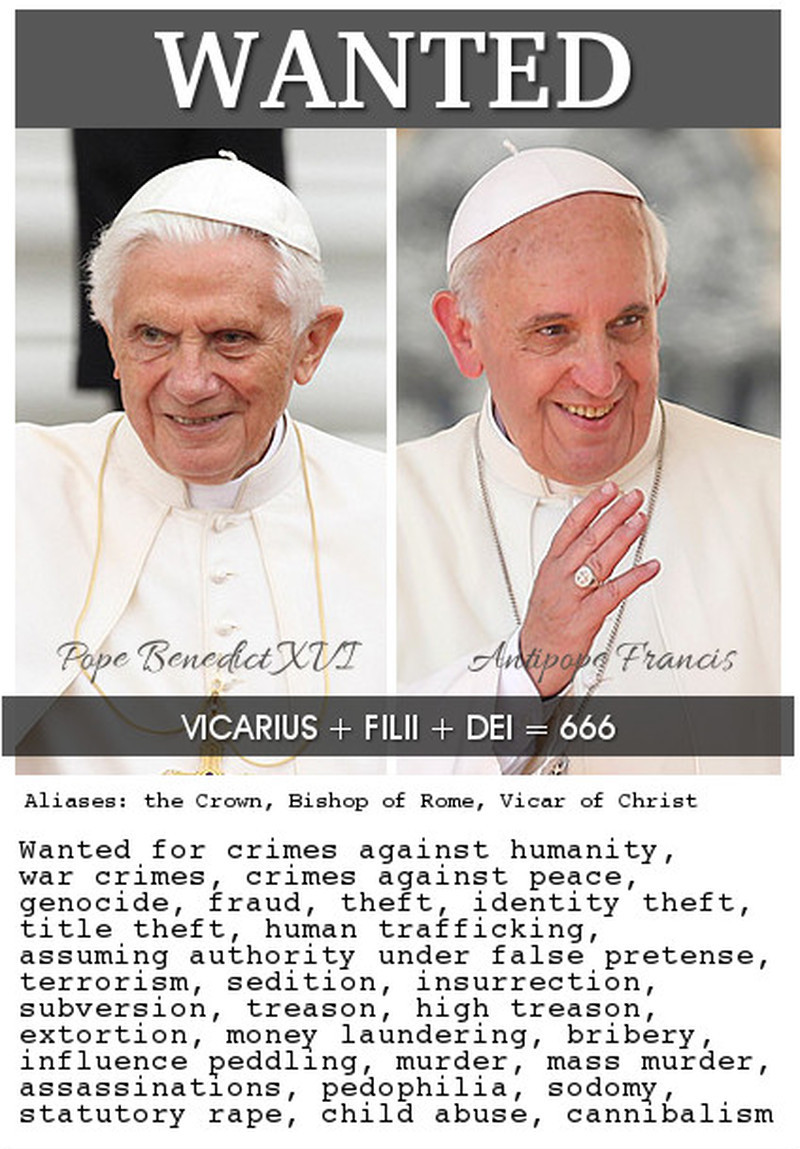

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online  Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Brewer’s or bread making yeast can be used to increase your septic tank natural gas production. Brewer’s or bread making yeast keeps the bacteria active in your septic system. Septic tanks depend on bacteria to break down solids. You can prevent sludge buildup and keep the bacteria in the septic tank working hard for you by flushing the following mixture:

* 2 cups refined sugar, (unhealthy for human consumption as it is the fuel for cancer, bacteria and pathogens. The cure for cancer is to stop consuming refined sugar. Bacteria, cancer cells and pathogens love refined sugar. It is their essential fuel. So instead of consuming it and prevent cancer, disease and virus infections, flush it down the toilet and feed the septic tank bacteria so that they can go to work and break down the septic tank solid waste)

* 1 package active dry yeast, (bread making yeast from your grocery store)

* 1 quart of warm water.

Mix thoroughly, pour into the toilet bowl, and flush once a month.

Flushing a packet of brewer’s dry yeast down the toilet once a month will help add “good” bacteria to your septic tank and increase the break down of the septic tank waste into ethanol and energy.

How can brewer’s yeast produce ethanol and energy? Yeast is a single-celled fungus that lives naturally on the surface of fruit. It is essential in brewing and bread-making. Yeast respires anaerobically (i.e. without the use of oxygen) and breaks down glucose (sugar, carbohydrates) and produces carbon dioxide, ethanol (alcohol) and energy. In wine-making the yeast feeds on fruit sugars in the grapes, and in beer-making it feeds on the maltose sugar in germinating barley.

Brewers yeast is very effective in breaking down septic tank solids (human waste) and controlling odours but it will not work if the tank has had chemical toilet fluids like Elsan Blue added to it in the past. The toxic toilet chemicals kills the yeast before it can get to work and convert human waste into ethanol (alcohol) and energy. If you’ve used chemical treatments in the past you may have to flush the tank out and keep adding the yeast for several pump-outs before the brewer’s yeast can help you increase your septic tank natural gas production.

No room on top of your septic tank to bury a collector tank? No problem. Use a new or used air compressor tank (or truck air brake tank) as the natural gas collector. Place the air compressor tank on the surface, in an existing barn or shed or in a flower bed and run a gas line from it to the septic tank.

Gas will rise up out of the septic tank, through the gas line you buried in the ground to your air compressor tank on the surface. No excavation of the top of the septic tank is required when you use an air compressor tank on the surface. Just drill a 3/4″ hole into the ground and into the septic tank like they do when they drill for real oil and natural gas – not that fake snake oil and fabricated shale by fracking water.

Shale gas companies and politicians are lying (a fraud) when they describe Hydraulic fracturing, or “fracking” as the process of drilling and injecting fluid into the ground at a high pressure in order to fracture shale rocks to release natural gas. Shale is rock – 100% rock. Shale contains zero natural gas. They are fracking water not the rocks called shale and releasing water’s natural gases – hydrogen and oxygen. Water is H2O – Hydrogen (H2) and Oxygen (O). Both hydrogen and oxygen are combustible natural gas fuels

To trick you into believing sedimentary rock, called shale, is natural gas they mix up a very toxic chemical cocktail of mostly sulfuric acid and add the water to produce H2S – Hydrogen sulfide – a colorless gas with the characteristic foul odor of rotten eggs. H2S is heavier than air, very poisonous, corrosive, flammable and explosive. Hydrogen sulfide and oxygen burn with a blue flame. This very poisonous H2S blue flame is being fraudulently marketed as natural gas.

To entice investors into investing in this fraud they pump liquid propane under high pressure into the hole to deceptively mimic a natural gas find and to increase gas production from the well (hole in the ground). Propane is a natural gas. Propane already smells like rotten eggs so investors are duped into thinking that the conman has found natural gas.

Shale is 100% dirt. It contains zero oil or gas. You need water, lots of water, to fabricate what they fraudulently call shale gas. You need water, lots of water, to fabricate diluted tar from Alberta’s tar mining pits. Take away the water and there is no Alberta Tar Sands or poisonous H2S gas.

In 2005 scientists in Singapore developed a battery powered by urine. Just a single drop of urine is added to the cell and a chemical reaction takes place that produces electricity. The prototype battery produced about 1.5 volts, the same as a standard AA battery, and runs for about 90 minutes using a single drop of urine (uric Acid) http://news.nationalgeographic.com/news/2005/08/0818_050818_urinebattery.html

Now imagine how much “free’ electrical power you can generate, year round, from a prefab septic tank that are built to hold 1200 gallons of uric acid.

Lead–acid batteries were invented in 1859 by French physicist Gaston Planté. They are the oldest type of rechargeable battery. Lead-acid batteries use a chemical reaction to do work on charge and produce a voltage between their output terminals. So wouldn’t substituting the lead-acid with uric acid also produce a voltage between their electrodes? By George yes. All acid solutions can produce a voltage.

Volta discovered in 1800 that certain fluids would generate a continuous flow of electrical power when used as a conductor. This discovery led to the invention of the first voltaic cell, more commonly known as the battery. Volta discovered further that the voltage would increase when voltaic cells were stacked on top of each other. In the same year, Volta released his discovery of a continuous source of electricity to the Royal Society of London.

In 1802, Dr William Cruickshank designed the first electric battery capable of being mass produced. Cruickshank arranged square sheets of copper with equal sheet sizes of zinc. These sheets were placed into a long rectangular wooden box and soldered together. Grooves in the box held the metal plates in position. The sealed box was then filled with an electrolyte of brine, or watered down acid, resembling the flooded battery that is still with us today.

A septic tank (a huge underground sealed box) is full of an electrolyte of watered down uric acid. That makes a septic tank one massively big battery, wouldn’t you agree?

Using your septic tank system to produce your own free natural gas means no water theft and air (produces acid rain), land and water poisoning shale gas fabrication. Very toxic and life threatening tailing and evaporation ponds are produced by fabricating shale gas from dirt. The water that is stolen is contaminated and poisoned and rendered unfit for human or animal consumption.

Here is a simple solution to clean up and decontaminate the oil and gas tailing and evaporation ponds. Bacteria and gas are released from tailings and evaporation ponds. Construct domes made from recovered recyclable plastic over them and collect and burn the gas in on-site gas powered generators instead of letting it contaminate the air. The benefits are 3 fold:

– it would reduce the heavy consumption of natural gas in the oil refining process

– it would reduce the environmental impact of the toxic tailings ponds

– it would drastically reduce the release of greenhouse gases