How to convert your beloved gas guzzler into an eco friendlier high mileage gas vapor vehicle.

Getting Off Oil, World news Friday, September 7th, 2012

All gasoline combustion engines run more efficiently on a gas vapor. The proof is demonstrated every day by vehicles that run on propane or natural gas. You can convert any gas guzzling vehicle into a high mileage vehicle simply by running it on gasoline vapor. How many taxi companies Worldwide have converted their gasoline vehicles to run on the cheaper and environmentally friendlier propane or natural gas? Taxis throughout the US and Canada have kept the stock gasoline combustion engine but have modified them to run on propane or natural gas.

Propane and natural gas have been used as a commercial motor fuel for more than 80 years and billions of miles. Propane and natural gas powered engines offer cleaner emissions along with 10 to 15 percent less carbon dioxide, 20 percent less carbon monoxide and 50 to 60 percent less hydrocarbons and nitric oxide.

Most carburetor and fuel-injected engines can easily be modified to operate on propane or natural gas simply by installing a conversion kit. And propane and natural gas’s minimal sooting, owing to its low carbon content, means increased engine life, fewer oil changes and longer spark plug life.

Don’t be discouraged by claims that if you run you engine on only gas vapor or a leaner (less fuel more air) fuel mixture you’ll kill your engine. Propane and natural gas are the leanest types of fuel (they are both gas vapors) yet they have been used for over 80 years and they have caused no damage to the engine. They have actually extended the life of the engine. I have personally seen propane powered taxi cabs with over a million kilometers on their odometer.

Damage to an engine is caused by overheating (faulty coolant system), lack of oil, and carbon buildup in the engine from using liquid carbon fuels like gasoline and diesel. All gas vapor powered engine run cooler and cleaner than any liquid fuel feed engine. All gas vapor powered engines can travel a lot further than liquid fueled engines. Canadian auto mechanic and inventor Charles Nelson Pogue proved this 80 years ago. Pogue developed a gas vapor carburetor that allowed a Ford V-8 Coupe to travel 800% farther than its stock liquid fueled counterpart.

Even the US government knows that gas vapor and not liquid fuel is what runs all internal combustion engines. FEMA – “All internal combustion engines actually run on vapor, not liquid. The liquid fuels used by gasoline engines are vaporized before they enter the combustion chamber above the pistons.” This claim was stated in the following FEMA (Federal Emergency Management Agency) document – www.woodgas.net/files/FEMA_emergency_gassifer.pdf This report was published in 1989.

So, if millions of vehicles Worldwide are already running on propane and natural gas, it is safe to say that all liquid gasoline combustion engines can run on propane, natural gas or just the gasoline vapor. It is a lot cheaper to modify the existing liquid gasoline tank and produce gas vapor than to buy and install a propane or natural gas conversion kit.

How to convert your gas guzzler into a high mileage gas vapor vehicle

If you have the auto mechanical skill or know-how you could easily modify any existing liquid gasoline fuel system and make it into a liquid fuel to gas vapor system. You need only modify the fuel sending unit of the vehicle. I would suggest going to your local wrecker and buy a good used one instead of modifying the existing fuel sending unit if your vehicle is pretty new.

You don’t need to drill or cut into your existing liquid gasoline tank at all. You need only to modify the fuel pump / fuel sending unit by connecting a stainless steel aerator, that you install on the bottom of the gas tank, to the sending unit’s fuel sending line and have the modified fuel sending system vacuum the accumulated fuel vapor from the top inside of the liquid gasoline fuel tank – see image below. This simple system converts the liquid fuel in your liquid gasoline tank into a gas vapor through a process called aeration.

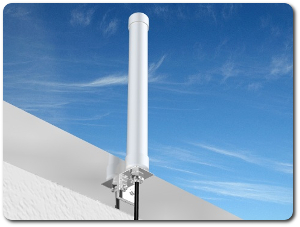

To make this system work efficiently install a mass produced store bought air tank in the trunk of your vehicle and use as a gas vapor collector and reserve tank – see article image above. Attach a flexible gas line to the securely installed air tank and connect the opposite end of that line to the return fuel port of the modified fuel sending unit. Your preexisting fuel sending line – that goes to the engine from the liquid gasoline fuel tank – will be connected to the air tank in the trunk instead of the liquid gasoline fuel tank.

The modified gas vapor fuel system works by vacuuming the gas vapor from the top of the liquid gasoline tank, through the flexible fuel line between the gas tank and the installed air tank in the trunk, into and from the air tank and along the preexisting fuel sending line to the engine.

You could use a mass produced air compressor type tank or commercial truck air brake tank or a propane conversion type fuel tank as the gas vapor collector and reserve tank. All are already made to withstand very high air (which is also a gas) pressures and the tank will act like a reserve tank when the engine is off. This way you will always have a good supply of gas vapor to draw upon.

Liquid gasoline to gas vapor conversion process

If your gas guzzler’s fuel sending unit looks like the above you can easily modify it by simply switching the fuel supply line for the fuel return line. The fuel supply line now becomes the fuel return line and vise versa. Securely connect a stainless steel aerator to the end of the original fuel supply line (the longest of the 2 lines).

The electrical power to the fuel pump can be disconnected as the engine vacuum already pumps the unburned fuel through the return line and back into the gas tank. The return fuel line now acts as a pump and can now pump the warmer gas/air mixture from the engine back to the gas tank and through an attached aerator and produce gas vapor.

In today’s cars the fuel is constantly circulating from the tank, through the system and back to the tank. The fuel does not stay still long enough to get hot enough for it to begin to vaporize. This is the whole purpose of the return fuel line. It is preventing the fuel from vaporizing and it is preventing much higher fuel mileage.

Your vehicle runs on fuel vapor not liquid. The more you vaporize (gasify) the liquid fuel the greater the fuel mileage. Since all new cars have these return fuel lines you can take advantage of it and produce high mileage fuel vapor. The returned fuel from the engine is always warmer than the fuel supply line. Heat aids in the vaporization (gasification) of the liquid fuel. Instead of cold air being injected into the gas tank and producing cold air bubbles the return fuel line can be used to inject a much warmer air/fuel gaseous mixture and produce warm air/fuel gaseous bubbles. What was purposely manufactured into all new cars to keep fuel efficiency low can be used to actually increase fuel efficiency.

In the above it is stated that the electrical power to the fuel pump can be disconnected. Actually, the pump can serve a purpose. Add an on/off dash mounted switch and reverse the electric polarity of the pump and you could use the pump as a gas vapor fuel primer. Before you turn the ignition on for your vehicle, toggle the dash on/off switch intermittently a few times to activate the fuel pump for a few seconds so that the fuel pump can reverse pump enough air through the aerator to generate enough gas vapor and pressure to start the engine. Once the engine fires engine vacuum will take over and you will no longer need the fuel pump to be on. This is how pilots start their gas powered engines. They intermittently activate a fuel boost pump to prime the engine prior to start. The pump adds a small amount of fuel at the cylinder intakes to assist in starting a cold engine.

Greater fuel efficiency using only the gasoline vapor

How much more fuel will you have to utilize by just using the gasoline vapor? Using a common industrial formula the saturated vapor volume of an average gallon of liquid gasoline when fully evaporated is 160.4 gallons of vapor at 60° F and sea level. So instead of your gas guzzler getting only 20 mpg you now can get 160 times the mpg (miles per gallon) or 3200 mpg. Even if we only get 10 gallons of gasoline vapor from 1 gallon of liquid gasoline we would still be increasing our vehicle’s fuel efficiency 10 fold or 200 mpg.

Common industrial formula:

one liquid gallon = [(8.31) x (SG) x (387 cu ft)] / (MW)

Where:

8.31 = pounds in gallon of water

SG = specific gravity of liquid being vaporized

387 = At standard conditions, one pound-molecular weight of a material will evaporate to fill 387 cubic feet of space.

MW= molecular weight of liquid being vaporized

Then using the approximate gasoline constants:

one liquid gallon of gasoline = [(8.31 pounds in a gallon of water) x (.70 approx. specific gravity of gasoline) x (387 cu ft)] / (105 molecular weight of average gasoline)

= 21.4 cubic feet of vapor volume

There is 7.481 U.S. gallons in one cubic foot.

So: one liquid gallon of gasoline = (21.4 cubic feet) x (7.481) = 160.4 gallons of saturated gasoline vapor

The vapor volume will vary based on the specific formulation of gasoline, pressure, and temperature.

Nearly a century of developing eco friendlier high mileage gas vapor vehicles

Gasoline in a vapor form is better because it has a larger surface area for the reaction (combustion) to take place. The concept of gasoline vapor induction goes back at least as far as 1915 with patents illustrating how gasoline in a gaseous state is explosive, hence dynamic. Gasoline in a liquid state must be converted to a gas before burning can take place; it’s the rapid burning that causes the air and fuel mixture to expand, hence a downward force during the power (down stroke) stroke of a piston in a reciprocating engine.

Since vaporization occurs for the burning process to conclude, Gasoline Vapor Induction (also referred to as GVI) simply pre-stages the gasoline to release the hydrocarbon in a gas form early on in the process. This phase change allows the hydrocarbon to release its energy dynamically (like a stick of dynamite) versus thermally (like a corked tea kettle as it starts to boil).

In order to convert from a liquid to a gas the atmospheric pressure must be overcome. One common way to do this is to add heat (increase the average ambient kinetic energy per cubic inch) until the molecules are excited enough to break free from the meniscus of the liquid. This is a high-energy mechanism to accomplish a natural phase change in matter.

A low-energy solution was discovered by inventor George Talbert in the 1960’s; remove the atmospheric pressure and the liquid converts to a gas in favor of its’ self-defining properties. Gasoline releases the hydrocarbons in gaseous form readily at less than one atmosphere.

How can you remove the atmospheric pressure and allow the liquid gasoline to easily convert to a gas? Use the engines vacuum. When the piston travels its’ down stroke path into the cylinder of the gas combustion engine block, a vacuum it created. That vacuum (suction) causes the atmospheric pressure in the gas vapor collector and reserve tank (air tank you install in the trunk of your car or box of your pickup) to be reduced causing the fuel to convert to a very fine atomized mist.

It was proven possible in 1933, that gas combustion engines can get a fuel efficiency of 200 mpg – by Charles Nelson Pogue. Canadian inventor, Charles Nelson Pogue invented a carburetor that vaporized gasoline, instead of nebulizing it into tiny drops, thus dramatically increasing mileage per gallon of gasoline used. In 1933 Charles Nelson Pogue made headlines when he drove a 1932 Ford V8, 200 miles on a gallon of gas during a demonstration conducted by The Ford Motor Companies in Winnipeg, Manitoba using his super-carb system.

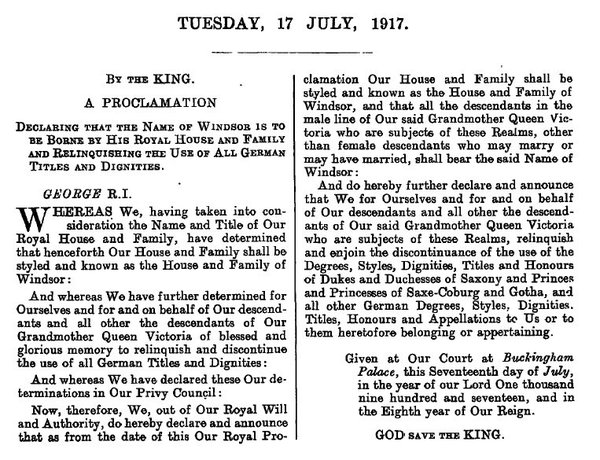

United States Patent # 750354 http://www.freepaten … 354&stemming=on (Download .pdf 1750354 ) Many people attested to these mileage claims as The Pogue Carb went into production and was sold openly. However, one of the crucial factors of these systems is the use of “white” gasoline, which contained no additives. It was at this time oil companies started adding lead to the fuel. Lead is an anti-catalyst that rendered Pogue’s carburetor as inefficient as a regular carb.

His invention caused such shock waves through the stock market, that the US and Canadian governments both stepped in and applied pressure to stifle him. He suffered an enormous amount of loss as a result of trying to make the world a better place.

Mr. Pogue’s vaporizer brought him in contact with a lot of people who didn’t want what he was offering to get out. He received many accolades, and was accused by others as being a fraud. Lead was intentionally added to gasoline to prevent anyone else from building such a device, since lead leaves heavy deposits and clogs these types of units, rendering them ineffective due to the inability to transfer heat to the fuel.

Pogue wasn’t the only one to substantially increase the fuel efficiency of the gas combustion engine. Tom Ogle of El Paso Texas , a 24 year old mechanic drove 200 miles in a 1970 351 ci. Ford on 2 gallons of gas. Other mechanics and engineers checked for hidden tanks, none were found. Reporters and a camera crew went with him 100 miles out and back; 200 miles 2 gallons. He claimed from the beginning that he did not know exactly how the system worked, just that it did and he proved it time and again. He had hoped other engineers would help to explain what he was doing. He had a hard time getting backers that had integrity. Everybody wanted controlling interest and he knew it was going on the back shelf. Tom resisted and tried to get it on the market. Later he was shot and survived, only four months later he did die of an overdose of darvon and alcohol with no suicide note. Nobody explained what became of his idea. A patent was issued Dec. 11, 1979 # 4,177,779 – Four months after his death.

United States Patent 4177779 http://www.freepaten … ine.com/4177779.html

Patent Abstract – A fuel economy system for an internal combustion engine which, when installed in a motor vehicle, obviates the need for a conventional carburetor, fuel pump and gasoline tank. The system operates by using the engine vacuum to draw fuel vapors from a vapor tank through a vapor conduit to a vapor equalizer which is positioned directly over the intake manifold of the engine. The vapor tank is constructed of heavy duty steel or the like to withstand the large vacuum pressure and includes an air inlet valve coupled for control to the accelerator pedal. The vapor equalizer ensures distribution of the correct mixture of air and vapor to the cylinders of the engine for combustion, and also includes its own air inlet valve coupled for control to the accelerator pedal. The system utilizes vapor-retarding filters in the vapor conduit, vapor tank and vapor equalizer to deliver the correct vapor/air mixture for proper operation. The vapor tank and fuel contained therein are heated by running the engine coolant through a conduit within the tank. Due to the extremely lean fuel mixtures used by the present invention, gas mileage in excess of one hundred miles per gallon may be achieved.

Even with lead added it was proven possible to get a fuel efficiency of 100 mpg in 1970. Then three years later in 1973 a souped-down 1959 Opel T-1 achieved 376.59 miles per gallon. Featured in the Guinness Book of World Records. Using fully stock production gasoline engine powered vehicles, with engine modifications limited only to changes in fuel mixture and ignition timing, Shell Oil Company served host to an open competition in automobile efficiency. The fruit of their forum was sweet indeed as a two-door, full-sized production car was able to drive off with the prize by achieving 376.59 miles in normal driving conditions using a single gallon of fuel. A more heavily modified vehicle was able to achieve over 1140 miles on a single gallon of fuel. Results like these are truly astounding and beg the question: Are we really getting all we can in efficiency from auto makers?

Short URL: https://presscore.ca/news/?p=6898

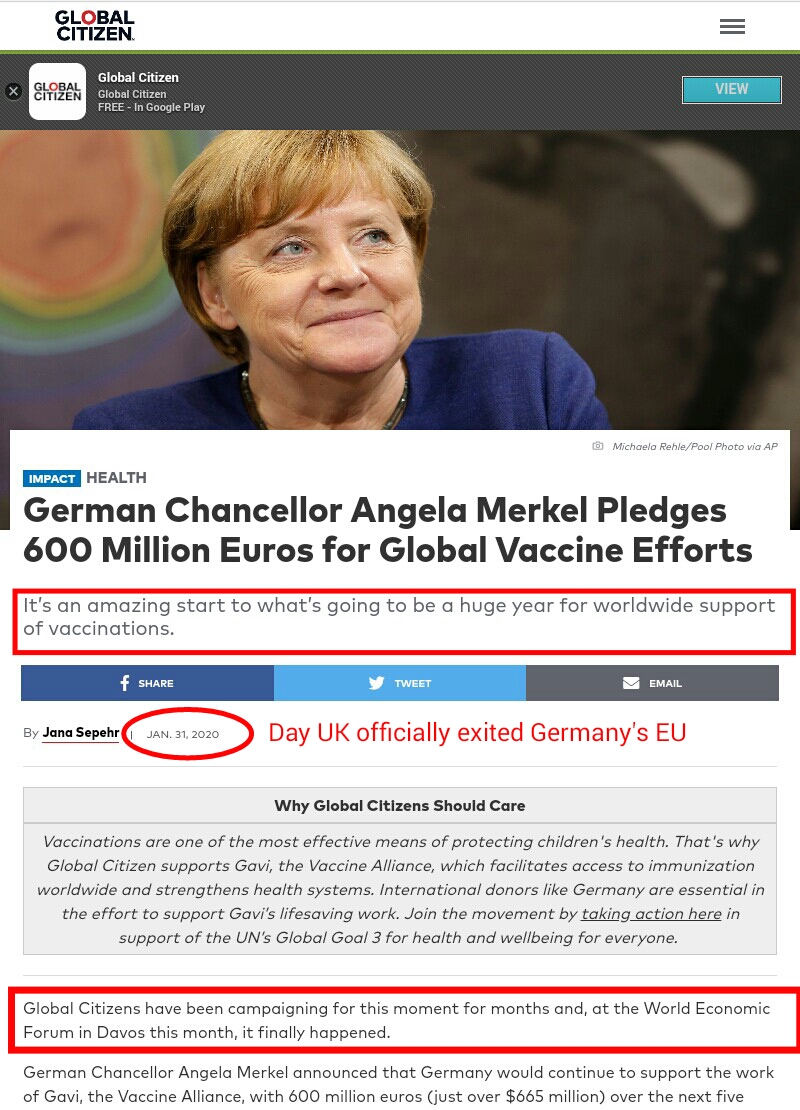

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

Please take a moment to sign a petition to

Please take a moment to sign a petition to

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online  Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Above image is from the Alberta government website – http://www.energy.alberta.ca/OilSands/1719.asp What do you see? Dirt or oil? Sand truck or oil tanker?

Tar sludge is a hazardous waste that is a by-product of the tar cooking process. It is a dark, sticky substance that poses serious threats to human health, environmental standards and worker safety. That is exactly what Canadian oil is – tar sludge. The stripped mined tar sands of Alberta is cooked, using fresh drinking water, to purposely make this very toxic tar sludge. They then refine this very toxic by-product using more toxic solvents to dissolve away the substance of interest – counterfeit oil.

The true test as to whether or not Alberta Tar sand is oil or not is easily demonstrated by the fact that natural petroleum will burn straight from the ground. Alberta Tar Sand will not. Oil tankers and oil platforms can explode with just a small spark. You can spray an Alberta Tar sand strip mine with a flame thrower and it won’t explode. If you smoke on or near an oil rig you can cause a catastrophic explosion and fire. Strip miners at the Alberta Tar sand pits can smoke and even throw their lite cigarette butts on the exposed Alberta Tar Sand and it won’t cause an explosion or instantaneous fire.

It is a well documented fact that air pollution from internal combustion engines is caused by unburned carbon fuel. Today, all gasoline powered vehicles burn only finely divided particles or droplets that are sprayed from the carburetor or fuel injectors, into the engine cylinders. This is a very wasteful process of converting gasoline or diesel to energy. 20-30 % efficiency at best. Converting liquid gasoline to a gasoline vapors will easily give 5 times the mpg and near zero emissions.

In the old days engines ran very lean as demonstrated by the fuel needle valve. In the old days just 1 tiny needle valve did the work of 6 to 8 fuel injectors. In the old days all engines ran on a much leaner amount of (less) fuel.

All internal combustion engines were made to run on highly combustible vapor, not liquid. It is well known that fuel-lean running improves the fuel efficiency of all vehicles. In the old days, under cruising conditions, the carburetor engines always ran lean – about 15% excess air. In the old days liquid fuel was reduced (made leaner) to finely divided particles or droplets before they enter the combustion chamber above the pistons. The carburetors reduced the liquid fuel into a very lean fuel mist before the fuel entered the combustion chamber above the pistons. Very high gas mileage is achieved by simply reducing liquid fuel into what all combustion engine need – gas vapor.

Vapor burns much cleaner than gasoline and has a higher octane rating. A lean running engine (ie, an engine using more air than fuel) has a cooler combustion process than the typical ECM engine with a preset (never deviating) chemically correct mixture of 14.6 air : 1 fuel. Running cooler is also better for the engines. Cooler running engines means a reduction in heat damage and failure.

In the early 1930s, Charles Nelson Pogue equipped a Ford V8 coupe with a vapor carburetor he designed and built and got over 200 MPG. He drove the V8 Ford from Winnipeg, Manitoba Canada to Vancouver B.C. Canada. He traveled 1879.5 miles on just 14.5 gallons of gasoline (the entire distance on just 3/4 of a 20 gallon tank of fuel) A standard carburetor used 106.5 gallons (or five, 20 gallon tanks of fuel) on the same trip.

In 1977, Tom Ogle demonstrated a 351 ci. Ford getting over 100 miles per gallon. He used a multiple fuel vaporizing system that had a 3 gallon tank. His system used heat to vaporize the liquid fuel. He received patent number 4,177,779 on Dec. 11, 1979, which described “A fuel economy system for an internal combustion engine which, when installed in a motor vehicle, obviates the need for a conventional carburetor, fuel pump and gasoline tank. The system operates by using the engine vacuum to draw fuel vapors from a vapor tank through a vapor conduit to a vapor equalizer which is positioned directly over the intake manifold of the engine.”

Liquid to gasoline vapor fuel system for your gas powered generator. Made in 2005 by © Paul W Kincaid

Here is an easy way to increase the fuel efficiency of all portable gas generators. It uses engine vacuum and a filtered air intake line to draw gas vapor from the liquid fuel. Gas vapor generation is enhanced by adding a circulation hose (for long term use replace the rigid plastic line in the image above with a flexible automotive grade fuel line hose) from the fuel petcock to a misting nozzle on the top of the tank. The engine vacuum will draw fuel out through the fuel petcock and into the attached circulation hose and sprayed out through the misting nozzle into the top of the tank. To prime a sufficient amount of gas vapor into the gas generator engine you will need to install a marine fuel primer pump on the vacuum line that feeds the vapor to the gas combustion engine – shown below. Pump the fuel primer several times to draw enough filtered air into the gas tank to generate enough gas vapor to start the engine. Once the engine fires engine vacuum will take over.

All portable gas generators wastes a lot of fuel. Liquid fuel is simply sprayed into the cylinders which isn’t a very efficient use of the very expensive fuel. Add the fact that the CO2 output of these generators are much higher than automobiles. You cannot run a gas generator indoors because the levels of CO2 are extremely high and it will kill you in a very short period of time.

The above described system to generate gas vapor from liquid fuel drastically lowers the emissions of the portable gas generator. In the process it can potentially increase the fuel efficiency by at least 10 fold. Less fuel will be wasted and the portable gas generators can run a lot longer. If your gas generator now runs 4 hours on a tank of fuel you could run it for as much as 40 hours using the same amount of liquid fuel.

If 1 gallon of liquid fuel equals 160 gallons of gas vapor how long do you think a portable gas generator will run if you feed it only gas vapor? Potentially 160 times longer. If your liquid to gas vapor system runs at full efficiency you could essentially run your gas generator for 640 hours (160:1 x 4) or 26.6 days. Even if you only get 10 times more running time, your fuel costs has decreased by 1000%.

If you don’t want to drill holes into the tank of your new and expensive gas generator you can convert your gas generator to a gas vapor system simply by drilling and setting the ports into the gas cap or a replacement gas cap that you can buy from the manufacturer. This way you can experiment with the above gas vapor fuel system and still have an original gas generator, if you mess up.