Exponentially increase your vehicle’s fuel mileage by using only the gas vapor from the top of your gas tank.

Getting Off Oil, World news Thursday, April 5th, 2012

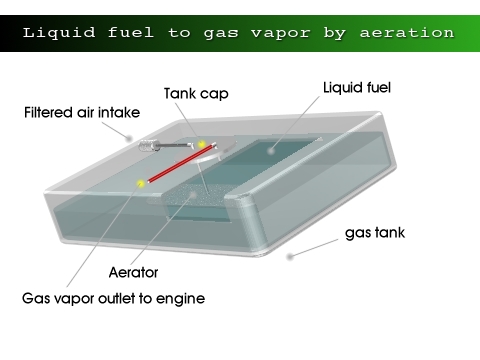

You can convert the liquid fuel in your gas tank into a very high fuel efficiency gas vapor simply by modifying the gas tank. You don’t need to drill or cut into the gas tank at all. You need only to remove the fuel pump / fuel sending unit and replace it with a vacuum line and a filtered air intake line that is attached to an aerator you install on the bottom of the gas tank and have it vacuum the accumulated fuel vapor from the top inside of the tank. This simple system converts the liquid fuel in your gas tank into a gas vapor through a process called aeration.

The filtered air intake (install a check valve between the filter and gas tank to only allow one way air flow to the tank) draws in oxygen into the bottom of the gas tank through the air intake line and attached aerator. The aerator creates very tiny air bubbles that attracts liquid fuel molecules as it rises to the surface of the liquid fuel. Once the air bubbles breaks the surface of the liquid fuel the air becomes a gas vapor. This gas vapor is then sucked up (vacuumed) into the vacuum fuel line and feed into the gas combustion engine. A fuel aerator functions much like an aquarium aerator which are used worldwide to oxygenate a fish tank.

You can add a secondary air tank to the system and have the engine vacuum draw the gas vapor from it. You could use a mass produced air compressor type tank as the gas vapor collecting and feed tank. They are already made to withstand very high pressures and the tank will act like a reserve tank when the engine is off. This way you will always have a good supply of gas vapor to draw upon.

This will actually work. For 8 decades now the oil companies and your government have known that much greater fuel efficiency is possible for all vehicles. Since the 1930s Ford had the technology to produce cars that got as much as 200 mpg – as demonstrated by Charles Nelson Pogue and the Ford Motors of Canada.

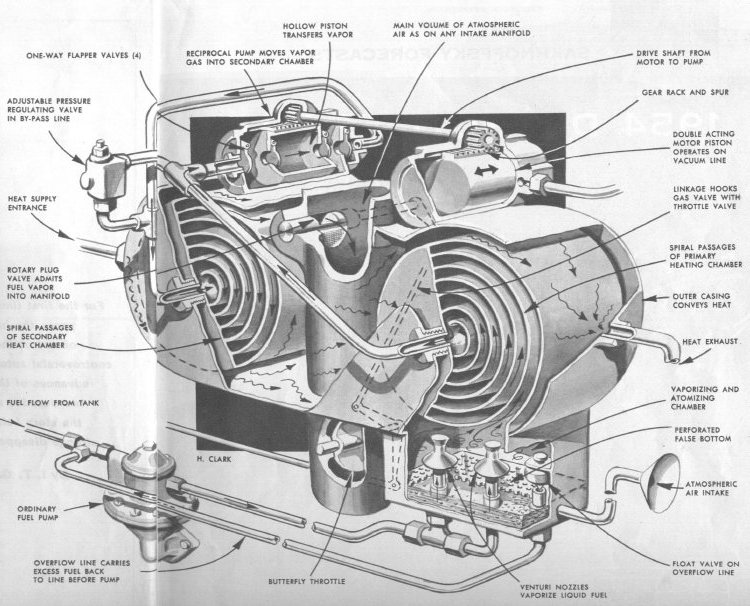

In 1933 Charles Nelson Pogue made headlines when he drove a 1932 Ford V8, 200 miles on a gallon of gas during a demonstration conducted by The Ford Motor Company in Winnipeg, Manitoba using his super-carb system.” How was he able to travel so far on just 1 gallon of liquid gasoline? He vaporized the liquid fuel from the gas tank. He used heat (hot air) to convert the liquid fuel into a very high mileage gas vapor. The vaporization occurred just before it entered the cylinder heads of the engine. But you can convert liquid gasoline into a high mileage gas vapor fuel simply by using a vacuum to suck air into the gas tank and and through an aerator and as the aerator produced air bubbles rises through the liquid fuel they attract fuel molecules and becomes a highly combustible gas vapor.

In early 1936 Breen Motor Company, Winnipeg, Manitoba, Canada tested the Pogue carburetor on a Ford V-8 Coupe and got 26.2 miles on one pint of gasoline. 1 US pint = 0.125 US gallons. That means the Ford V-8 Coupe got 209.6 mpg. In Dec. 12, 1936 Canadian Automotive Magazine stated that the standard carburetor gets about 25 mpg at only 9% efficiency. The Pogue carburetor achieved 100% efficiency.

Need more proof that these things actually work? Need concrete evidence that all liquid gasoline combustion engines can run more efficiently on a gas vapor.? The proof that all gasoline powered engines run more efficiently on vapor than on liquid is propane and natural gas. How many taxi companies Worldwide have converted their vehicles to run on the cheaper and environmentally friendly propane or natural gas? Taxis throughout the US and Canada have kept the stock gasoline combustion engine but have modified them to run on propane or natural gas.

Propane and natural gas have been used as a commercial motor fuel for more than 80 years and billions of miles. Propane and natural gas powered engines offer cleaner emissions along with 10 to 15 percent less carbon dioxide, 20 percent less carbon monoxide and 50 to 60 percent less hydrocarbons and nitric oxide.

Most carburetor and fuel-injected engines can easily be converted to operate on propane or natural gas simply by installing a conversion kit. And propane and natural gas’s minimal sooting, owing to its low carbon content, means increased engine life, fewer oil changes and longer spark plug life.

Don’t be discouraged by claims that if you run you engine on only gas vapor or a leaner (less fuel more air) fuel mixture you’ll kill your engine. Propane and natural gas are the leanest types of fuel (they are both gas vapors) yet they have been used for over 80 years and they have caused no damage to the engine. They have actually extended the life of the engine. I have personally seen propane powered taxi cabs with over a million kilometers on their odometer.

Damage to an engine is caused by overheating (faulty coolant system), lack of oil, and carbon buildup in the engine from using liquid carbon fuels like gasoline and diesel. All gas vapor powered engine run cooler and cleaner than any liquid fuel feed engine. All gas vapor powered engines can travel a lot further than liquid fueled engines. Pogue proved this 80 years ago. Pogue gas vapor carburetor allowed the Ford V-8 Coupe to travel 800% farther than its stock liquid fueled counterpart.

Even the US government knows that gas vapor and not liquid fuel is what runs all internal combustion engines. FEMA – “All internal combustion engines actually run on vapor, not liquid. The liquid fuels used by gasoline engines are vaporized before they enter the combustion chamber above the pistons.” This claim was stated in the following FEMA (Federal Emergency Management Agency) document – www.woodgas.net/files/FEMA_emergency_gassifer.pdf This report was published in 1989.

So if millions of vehicles Worldwide are already running on propane and natural gas it is safe to say that all liquid gasoline combustion engines can run on propane, natural gas or aerated fuel vapor. It is a lot cheaper to modify the existing liquid gasoline tank and produce aerated fuel vapor than to buy and install a propane or natural gas conversion kit.

If you have the skill or know-how you could even modify your existing fuel sending unit and make it into a liquid fuel to gas vapor aeration system and ensure a perfect fit. I would suggest going to your local wrecker and buy a good used one instead of modifying the existing fuel sending unit if your vehicle is pretty new.

If your fuel sending unit looks like the above you can easily modify it by simply switching the fuel supply line for the fuel return line. The fuel supply line now becomes the fuel return line and vise versa. Securely connect a stainless steel aerator to the end of the original fuel supply line (the longest of the 2 lines).

The electrical power to the fuel pump would have to be disconnected as the engine vacuum already pumps the unburned fuel through the return line and back into the gas tank. The return fuel line can now pump the warmer gas/air mixture from the engine back to the gas tank and through the aerator and provide a richer air/fuel aeration of the liquid fuel.

In today’s cars the fuel is constantly circulating from the tank, through the system and back to the tank. The fuel does not stay still long enough to get hot enough for it to begin to vaporize. This is the whole purpose of the return fuel line. It is preventing the fuel from vaporizing and it is preventing much higher fuel mileage. Your vehicle runs on fuel vapor not liquid. The more you vaporize the liquid fuel the greater the fuel mileage. Since all new cars have these return fuel lines you can take advantage of it and increase the liquid fuel aeration and produce a richer fuel vapor. The returned fuel from the engine is always warmer than the fuel supply line. Heat aids in the vaporization of the liquid fuel. Instead of cold air being injected into the gas tank and producing cold air bubbles the return fuel line can be used to inject a much warmer air/fuel gaseous mixture and produce warm air/fuel gaseous bubbles. What was purposely manufactured into all new cars to keep fuel efficiency low can be used to actually increase fuel efficiency.

In the above it is stated that the electrical power to the fuel pump would have to be disconnected. Actually the pump can serve a purpose. Add an on/off dash mounted switch and reverse the electric polarity of the pump and you could use the pump as a gas vapor fuel primer. Before you turn the ignition on for your vehicle, toggle the dash on/off switch intermittently a few times to activate the fuel pump for a few seconds so that the fuel pump can force enough air into the gas tank to generate enough gas vapor and pressure to start the engine. Once the engine fires engine vacuum will take over and you will no longer need the fuel pump to be on. This is how pilots start their gas powered engines. They intermittently activate a fuel boost pump to prime the engine prior to start. The pump adds a small amount of fuel at the cylinder intakes to assist in starting a cold engine.

Short URL: https://presscore.ca/news/?p=5951

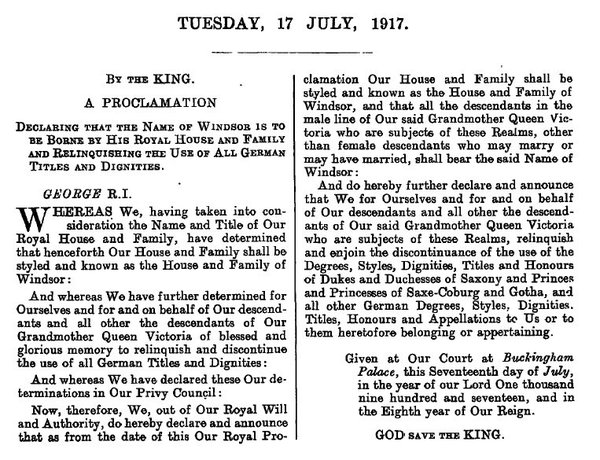

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

The Halifax International Security Forum was founded in 2009 as a propaganda program within the German Marshall Fund (founded June 5, 1972 by West German Chancellor Willy Brandt) by the Crown in Canada using Crown Corp ACOA & DND funds. The Halifax International Security Forum is a front that is used to recruit top US, UK and Canadian gov and military officials as double agents for Canada's WWI, WWII enemy and wage new Vatican Germany Cold War.

High Treason: s.46 (1) Every one commits high treason who, in Canada (c) assists an enemy at war with Canada, ..., whether or not a state of war exists". Every one who, in Canada assists Canada's enemies wage "piecemeal WWIII" Cold War by organizing, funding and participating in the Germany government politically and militarily benefitting / lead Halifax International Security Forum is committing high treason.

Please take a moment to sign a petition to

Please take a moment to sign a petition to

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

1917 Code of Canon Law, Canon 185 invalidates (voids) all papacies since October 26, 1958 due to the fact Cardinal Giuseppe Siri was elected Pope on the Third ballot on Oct 26 1958 but the new Pope Gregory XVII was illegally prevented from assuming the office. A Pope was elected on October 26, 1958. Thousands of people witnessed a new Pope being elected by seeing white smoke and millions were informed by Vatican radio broadcasts beginning at 6:00 PM Rome time on October 26, 1958. The papacy of Francis, Benedict, John Paul II, John Paul I, Paul VI, John XXIII and any and all of their respective doctrines, bulls, letter patents and the Second Vatican Council are all invalidated (having no force, binding power, or validity) by Canon 185 because the 1958 conclave of cardinals elected Cardinal Giuseppe Siri Pope on Oct 26 1958. Cardinal Giuseppe Siri accepted the papacy by taking the name Pope Gregory XVII but was illegally prevented from assuming his elected office.. According to Canon 185 Cardinal Angelo Giuseppe Roncalli illegally assumed the papacy 2 days later by fraud and grave fear, unjustly inflicted against Cardinal Giuseppe Siri who was lawfully elected Pope Gregory XVII. Because no Pope has been lawfully elected since October 26, 1958 the Holy See (la Santa Sede/Seat) remains vacant.

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online

Hold the Crown (alias for temporal authority of the reigning Pope), the Crown appointed Governor General of Canada David Lloyd Johnston, the Crown's Prime Minister (servant) Stephen Joseph Harper, the Crown's Minister of Justice and Attorney General Peter Gordon MacKay and the Crown's traitorous military RCMP force, accountable for their crimes of treason and high treason against Canada and acts preparatory thereto. The indictment charges that they, on and thereafter the 22nd day of October in the year 2014, at Parliament in the City of Ottawa in the Region of Ontario did, use force and violence, via the staged false flag Exercise Determined Dragon 14, for the purpose of overthrowing and besieging the government of Canada contrary to Section 46 of the Criminal Code. In a society governed by the rule of law, the government and its officials and agents are subject to and held accountable under the law. Sign the online  Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.

Two of the most obvious signs of a dictatorship in Canada is traitorous Stephen Harper flying around in a "military aircraft" and using Canadian Special Forces "military" personnel from JTF2 and personnel from the Crown's traitorous martial law "military" RCMP force as his personal bodyguards.